![Epelsiban.svg]()

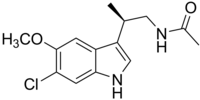

Epelsiban

557296

GSK-557296

GSK-557296-B

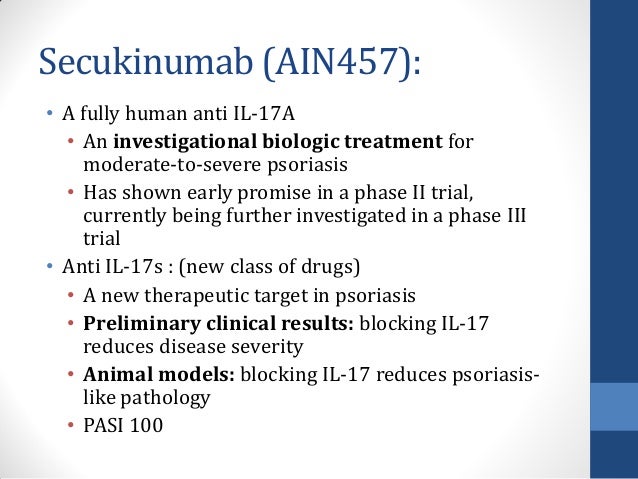

(3R,6R)-3-(2,3-Dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione

(3R,6R)-6-[(2S)-butan-2-yl]-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethylpyridin-3-yl)-2-morpholin-4-yl-2-oxoethyl]piperazine-2,5-dione

(3R, 6R)-3-(2,3-dihydro-1 H-inden-2-yl)-1-[(1R)- 1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1 S)-1-methylpropyl]-2,5- piperazinedione

Glaxo Group Limited INNOVATOR

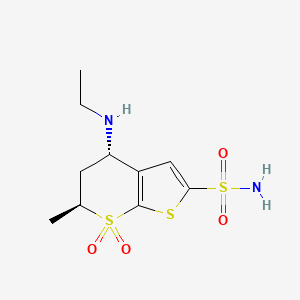

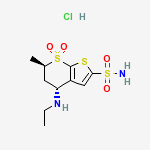

Epelsiban (GSK-557,296-B)[1][2] is an oral drug which acts as a selective, sub-nanomolar (Ki=0.13 nM) oxytocin receptor antagonist with >31000-fold selectivity over the related vasopressin receptors and is being developed by GlaxoSmithKline for the treatment of premature ejaculation in men.[3][4]

![]()

![A structure of EPELSIBAN BESYLATE EPELSIBAN BESYLATE.png]()

![]()

benzenesulfonic acid;(3R,6R)-6-[(2S)-butan-2-yl]-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethylpyridin-3-yl)-2-morpholin-4-yl-2-oxoethyl]piperazine-2,5-dione,CAS 1159097-48-9

UNII-H629P9T4UN, GSK557296B, Epelsiban besylate (USAN), Epelsiban besylate [USAN], 1159097-48-9, H629P9T4UN

GSK-557296 is being developed in early clinical studies at GlaxoSmithKline for enhancement of embryo and or blastocyst implantation in women undergoing IVF treatment. The product has been in phase II clinical development for the treatment of premature ejaculation.

Preterm labor is a major clinical problem leading to death and disability in newborns and accounts for 10% of all births and causes 70% of all infant mortality and morbidity.

Oxytocin (OT) is a potent stimulant of uterine contractions and is responsible for the initiation of labor via the interaction with the OT receptors in the mammalian uterus. OT antagonists have been shown to inhibit uterine contractions and delay preterm delivery. So there is increasing interest in OT antagonists because of their potential application in the prevention of preterm labor. Although several tocolytics have already been approved in clinical practice, they have harmful maternal or fetal side effects.

The first clinically tested OT antagonist atosiban has a much more tolerable side effect profile and has recently been approved for use in Europe. However, atosiban is a peptide and a mixed OT/vasopressin V1a receptor antagonist that has to be given by iv infusion and is not suitable for long-term maintenance treatment, as it is not orally bioavailable.

Hence there has been considerable interest in overcoming the shortcomings of the peptide OT antagonists by identifying orally active nonpeptide OT antagonists with a higher degree of selectivity toward the vasopressin receptors (V1a, V1b, V2) with good oral bioavailability. Although several templates have been investigated as potential selective OT antagonists, few have achieved the required selectivity for the OT receptor vs the vasopressin receptors combined with the bioavailability and physical chemical properties required for an efficacious oral drug.

Therefore our objective was to design a potent, orally active OT antagonist with high levels of selectivity over the vasopressin receptor with good oral bioavailability in humans that would delay labor safely by greater than seven days and with improved infant outcome, as shown by a reduced combined morbidity score.

| Patent |

Submitted |

Granted |

| Compounds [US7919492] |

2010-12-02 |

2011-04-05 |

| Piperazinediones as Oxytocin Receptor Antagonists [US7550462] |

2007-11-01 |

2009-06-23 |

| Compounds [US8202864] |

2011-06-23 |

2012-06-19 |

| Novel compounds [US2009247541] |

2009-10-01 |

|

………………………………………

PATENT

https://www.google.com/patents/US7919492

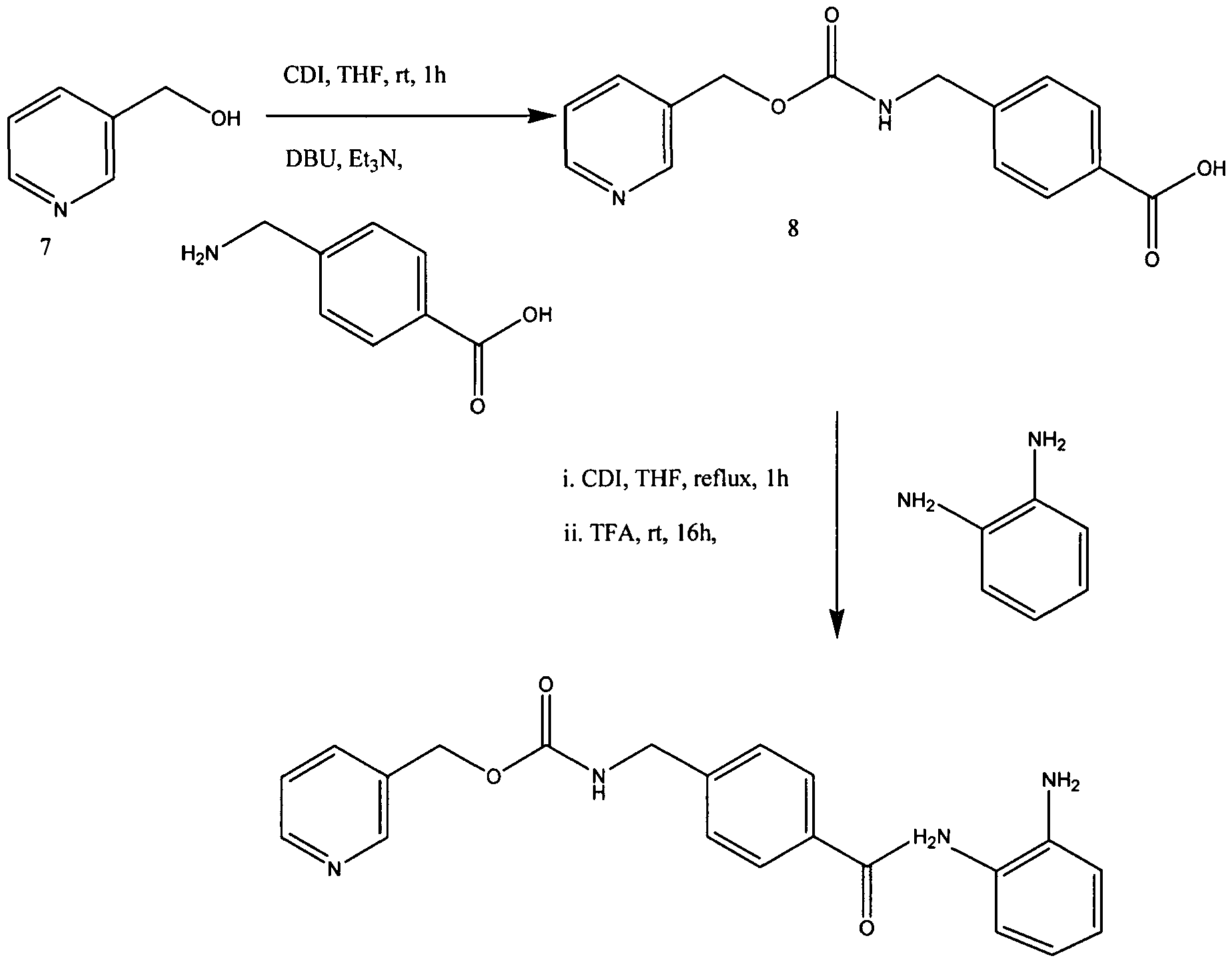

Example 3

Method A

(3R,6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione

as a white lyophilisate (88 mg, 23%) after freeze-drying from 1,4-dioxane

HPLC Rt=2.70 minutes (gradient 2); m/z [M+H]+=519

1H NMR (CDCl3) δ 7.49 (d, 1H), 7.27-7.15 (m, 4H), 7.10 (d, 1H), 6.68 (s, 1H), 6.40 (d, 1H), 4.10 (dd, 1H), 4.01 (d, 1H), 3.74-3.52 (m, 5H), 3.28-3.07 (m, 5H), 2.97-2.84 (m, 2H), 2.79-2.71 (m, 1H), 2.62 (s, 3H), 2.59 (s, 3H), 1.65-1.53 (m, 1H), 0.98-0.80 (m, 2H), 0.70 (t, 3H), 0.45 (d, 3H).

Example 3

Method B

(3R,6R)-3-(2,3-Dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione

A suspension of {(3R,6R)-3-(2,3-dihydro-1H-inden-2-yl)-6-[(1S)-1-methylpropyl]-2,5-dioxo-1-piperazinyl}(2,6-dimethyl-3-pyridinyl)acetic acid hydrochloride (5.0 g, 10.3 mmol) (intermediate 5) in dry dichloromethane (50 ml) was treated with 1,1-carbonyldiimidazole (2.6 g, 16 mmol) and the reaction mixture was stirred under nitrogen for 18 hours. Morpholine (4.8 ml, 55 mmol) was added and the resultant solution was left to stand under nitrogen for 18 hours. The solvent was removed in vacuo and the residue was separated between ethyl acetate and water. The organic phase was washed with brine and dried over anhydrous magnesium sulphate. The solvent was removed in vacuo and the residue was dissolved in dichloromethane. This was applied to a basic alumina cartridge (240 g) and eluted using a gradient of 0-7.5% methanol in diethyl ether (9CV), 7.5-10% methanol in diethyl ether (1CV) and 10% methanol in diethyl ether (1CV). The required fractions were combined and evaporated in vacuo to give (3R,6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione as a white solid (2.4 g, 45%).

HPLC Rt=2.72 minutes (gradient 2); m/z [M+H]+=519

………………………………………

WO 2011051814

http://www.google.com/patents/WO2011051814A1?cl=en

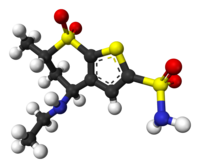

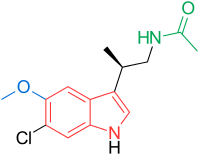

This invention relates to novel crystalline forms of (3R, 6R)-3-(2,3-dihydro-1 H- inden-2-yl)-1 -[(1 R)-1 -(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1 S)-1 – methylpropyl]-2,5-piperazinedione benzenesulfonate salt, processes for their preparation, pharmaceutical compositions containing them and to their use in medicine. The benzenesulfonate salt of Compound A is represented by the following structure:

In one aspect, the present invention provides a crystalline form of {3R, 6R)-3- (2,3-dihydro-1 H-inden-2-yl)-1 -[(1 -(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2- oxoethyl]-6-[(1 S)-1 -methylpropyl]-2,5-piperazinedione benzenesulfonate, wherein said crystalline form provides an X-ray powder diffraction pattern substantially in accordance with Figure 1 .

In another aspect, the invention encompasses a crystalline form of (3R, 6R)-3- (2,3-dihydro-1 H-inden-2-yl)-1 -[(1 -(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2- oxoethyl]-6-[(1 S)-1 -methylpropyl]-2,5-piperazinedione benzenesulfonate, wherein said crystalline form is characterized by an X-ray powder diffraction pattern comprising the peaks:

In an additional aspect, the invention includes a crystalline form of {3R, 6R)-3- (2,3-dihydro-1 H-inden-2-yl)-1 -[(1 R)-1 -(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2- oxoethyl]-6-[(1 S)-1 -methylpropyl]-2,5-piperazinedione benzenesulfonate hydrate, wherein said compound is characterized by an X-ray powder diffraction pattern substantially in accordance with Figure 2.

In certain aspects, the invention encompasses a crystalline form of (3R, 6R)-3- (2,3-dihydro-1 H-inden-2-yl)-1 -[(1 R)-1 -(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2- oxoethyl]-6-[(1 S)-1 -methylpropyl]-2,5-piperazinedione benzenesulfonate hydrate, wherein said compound is characterized by an X-ray powder diffraction pattern substantially in accordance with Figure 2 In one aspect, the invention also provides a crystalline form of {3R, 6R)-3-(2,3- dihydro-1 H-inden-2-yl)-1-[(1 R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]- 6-[(1 S)-1 -methylpropyl]-2,5-piperazinedione benzenesulfonate hydrate, wherein said crystalline form is characterized by an X-ray powder diffraction pattern comprising the peaks:

Experimental

Process Scheme

Stage 4

Acetone / Water Recrystallisation

Compound A-form I Ste8e 5 Besylate salt

MW 676.83 Acetone / Water

Recrystallisation MW 676.83 Process description for isolation of Compound A-Form 1

Stage 0

methyl d-alloisoleucinate hydrochloride (Compound 2) was charged to ethyl acetate. A solution of potassium carbonate in water was then added. The mixture was then stirred vigorously at room temperature for 1 hour. The two layers were separated and the aqueous layer further extracted with ethyl acetate. The organic layers were combined and washed with brine. The organic layers were then concentrated in vacuo and filtered to yield methyl D-alloisoleucinate (Compound 3) as a pale yellow oil.

Stage 1

2,6-dimethyl-3-pyridinecarbaldehyde (Compound 4) in methanol at ambient temperature was treated with D-alloisoleucinate (Compound 3) in methanol followed by 2,2,2- trifluoroethanol and the reaction mixture was warmed to 40°C. When formation of the intermediate imine (methyl A/-[(2,6-dimethyl-3-pyridinyl)methylidene]-D-alloisoleucine) was complete Compound 5 was added followed by 1-isocyano-2- [(phenylmethyl)oxy]benzene (Compound 6) and the reaction mixture was stirred at 40°C until formation of Compound 7 was deemed complete.

Stage 2

Palladium on carbon catalyst was treated with a solution of Compound 7 in methanol and 2,2,2-trifluoroethanol and diluted with acetic acid. The vessel was purged with nitrogen and the reaction mixture warmed to 50°C and hydrogenated at 4.0-4.5 barg. When the reaction was deemed complete it was cooled to ambient temperature and the catalyst removed by filtration and washed through with methanol. The organic solution of 2- {(3R,6R)-3-(2,3-dihydro-1 H-inden-2-yl)-6-[(1 S)-1 -methylpropyl]-2,5-dioxo-1-piperazinyl}- 2-(2,6-dimethyl-3-pyridinyl)-/\/-(2-hydroxyphenyl)acetamide (Compound 8) was concentrated at reduced pressure and then diluted with /‘so-propyl acetate and concentrated at reduced pressure.

The residue was diluted with /‘so-propyl acetate and washed with aqueous ammonia. The aqueous phase was separated and extracted into another portion of /‘so-propyl acetate. The combined organic phases were washed with water, concentrated by distillation at reduced pressure, diluted with /‘so-propyl acetate and concentrated by distillation at reduced pressure, to leave a concentrated solution of 2-{(3R,6R)-3-(2,3-dihydro-1 H-inden-2-yl)-6-[(1 S)-1 -methylpropyl]-2,5-dioxo-1 – piperazinyl}-2-(2,6-dimethyl-3-pyridinyl)-/\/-(2-hydroxyphenyl)acetamide (Compound 8). The product was finally dissolved in 1 ,4-dioxane for the next stage and stored into drums.

Stage 3 Solution of 2-{(3R,6R)-3-(2,3-dihydro-1 H-inden-2-yl)-6-[(1 S)-1 -methylpropyl]-2,5-dioxo-1 – piperazinyl}-2-(2,6-dimethyl-3-pyridinyl)-/\/-(2-hydroxyphenyl)acetamide (Compound 8) in 1 ,4-dioxane was treated with 1 ,1 ‘-carbonyl diimidazole at ambient temperature to form a solution containing (3R,6R)-3-(2,3-dihydro-1 H-inden-2-yl)-1 -[1-(2,6-dimethyl-3-pyridinyl)- 2-oxo-2-(2-oxo-1 ,3-benzoxazol-3(2H)-yl)ethyl]-6-[(1 S)-1 -methylpropyl]-2,5- piperazinedione (Compound 9).

In a separate vessel morpholine in 1 ,4-dioxane was heated to 80-85°C. The solution containing (3R,6R)-3-(2,3-dihydro-1 H-inden-2-yl)-1-[1 – (2,6-dimethyl-3-pyridinyl)-2-oxo-2-(2-oxo-1 ,3-benzoxazol-3(2H)-yl)ethyl]-6-[(1 S)-1- methylpropyl]-2,5-piperazinedione (Compound 9) was slowly added to the morpholine in 1 ,4-dioxane. The reaction mixture was stirred for one hour at 80-85°C and cooled before concentration by distillation at reduced pressure.

The concentrated solution of Compound A was diluted with /‘so-propyl acetate and washed with aqueous sodium hydroxide followed by water. The /so-propyl acetate solution of COMPOUND A was then concentrated by distillation at reduced pressure and cooled to ambient temperature. The concentrated solution of Compound A was then diluted with acetone and treated with benzenesulfonic acid and seed crystals were added and the reaction mixture stirred until crystallisation occurred. The slurry of Compound A besylate was heated to 50°C, a temperature cycle was performed, and finally the slurry was cooled to -10°C and isolated by filtration. The filter cake was washed with cold acetone (-10°C) to give Compound A besylate (intermediate grade) as a wet cake.

Yield: 44% from Compound 5

39% from Compound 5

Stage 4

Compound A besylate (intermediate grade wet cake, Compound A besylate ) was suspended in acetone (17.4 vol including acetone content of wet cake) and heated to 55- 60°C. Water (0.66 vol) was added until dissolution was observed. The reaction mixture was then filtered into another vessel and the lines washed through with acetone (3.2 vol). The temperature of the reaction mixture was adjusted to 45-50°C before the addition of seed crystals (0.00025wt). When crystallisation was complete the reaction mixture was cooled to 20-25°C and stirred at 20-25°C for 30mins.

The reaction mixture was heated to 45-50°C and stirred at 45-50°C for 30mins. The reaction mixture was cooled to 20-25°C and stirred at 20-25°C for 30mins. The reaction mixture was heated to 45-50°C and stirred at 45-50°C for 30mins. The reaction mixture was cooled to -3-2°C over 4.5 h and stirred for at least 1 h before the product was isolated by filtration. The wet cake was washed with acetone at 0°C (3 x 3.1 vol) and blown dry before being unloaded. COMPOUND A besylate was dried at 50°C under vacuum for 3 days. Compound A besylate was then milled. Yield: 66% Stage 5

Compound A besylate (OBU-D-02) was suspended in acetone (8 vol) and water (1 .1 vol) and heated to 48-52°C until dissolution was observed. The reaction mixture was then filtered into another vessel and the lines washed through with acetone (2 vol). The reaction mixture was cooled to 20-25°C before the addition of Form 1 seed crystals (0.0025wt). When crystallisation was complete the reaction mixture was cooled to 0-5°C over 1 h and stirred at 0-5°C for 30mins. The reaction mixture was heated to 20-25°C and stirred at 20-25°C for 30mins. The reaction mixture was cooled to 0-5°C over 1 h and stirred at 0-5°C for 30mins.

The reaction mixture was heated to 20-25°C and stirred at 20-25°C for 30mins. The reaction mixture was cooled to -12— 8°C over 3.5 h and stirred for 15 h before the product was isolated by filtration. The wet cake was washed with acetone at -10°C (2 x 3 vol) and blown dry before being unloaded. Compound A besylate was dried at ambient temperature under vacuum for 6 days with a wet nitrogen bleed to afford Form 1 . Compound A besylate was then milled. Yield: 67%

Recrystallisation of Compound A besylate anhydrate (Form 2)

Besylate salt ………………………………………………………………Besylate salt

C30H38 4O4■ C6H603S C30H38 4O4■

MW 676.83 MW 676.83

COMPOUND A besylate is charged to the vessel and treated with methyl ethyl ketone (MEK) (8vol) and water (0.35vol) and the solution heated until dissolution is observed (ca. 55-60°C). The solution is then filtered and recharged to the vessel. Pressure is then reduced to 650mbar and the reaction mixture heated further to distil out solvent. MEK is added at the same rate as solvent is removed by distillation keeping the reaction mixture volume constant. After 4 volumes of MEK have been added the reaction mixture is treated with Form 2 seed crystals (2%wt) and the distillation continued in the same manner until another 7 volumes of MEK has been added. The vacuum is then released to an atmospheric pressure of nitrogen and the temperature of the reaction mixture adjusted to 65°C. The reaction mixture is then filtered and washed with pre heated MEK (2vol at 65°C). The purified COMPOUND A besylate anhydrate is then sucked dry and dried further in a vacuum oven at 65°C at l OOmbar with a nitrogen bleed. Yield 89%

NMR data is the same for Forms 1 and 2.

1 H NMR (500MHz, DMSO-d6) 5ppm 0.71-0.80(m, 6H) 0.87-0.98(m, 1 H) 1 .31 (br. S, 1 H) 1.69(br. S, 1 H) 2.68(s, 3H) 2.69(s, 3H) 2.72-2.79(m, 1 H) 2.80-2.87(m, 1 H) 2.88-3.01 (m, 3H) 3.18-3.25(m, 1 H) 3.27-3.33(m, 1 H) 3.38-3.46(m, 1 H) 3.47-3.52(m, 1 H)3.53-3.57(m, 1 H) 3.60-3.71 (m, 3H) 3.83(dd, J=9.46,3.15 Hz, 1 H) 3.89 (br. S, 1 H)6.10(br. S, 1 H) 7.1 1 – 7.14(m, 2H) 7.19-7.23(m, 2H) 7.30-7.35(m, 3H)7.59-7.63(m, 2H) 7.67(d, J=7.25Hz, 1 H) 8.12(br. S, 1 H) 8.50(d, J=3.78Hz, 1 H)

Compounds of the present invention can be tested according to the description of International Publication No. WO2006000399 (US2007254888A1 ).

………………………………………..

PAPER

J. Med. Chem., 2012, 55 (2), pp 783–796

DOI: 10.1021/jm201287w

http://pubs.acs.org/doi/abs/10.1021/jm201287w

![Abstract Image]()

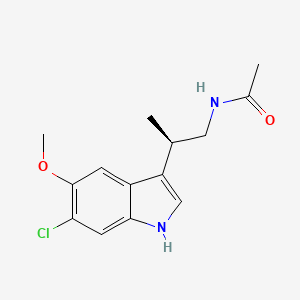

A six-stage stereoselective synthesis of indanyl-7-(3′-pyridyl)-(3R,6R,7R)-2,5-diketopiperazines oxytocin antagonists from indene is described. SAR studies involving mono- and disubstitution in the 3′-pyridyl ring and variation of the 3-isobutyl group gave potent compounds (pKi > 9.0) with good aqueous solubility. Evaluation of the pharmacokinetic profile in the rat, dog, and cynomolgus monkey of those derivatives with low cynomolgus monkey and human intrinsic clearance gave 2′,6′-dimethyl-3′-pyridyl R-sec-butyl morpholine amide Epelsiban (69), a highly potent oxytocin antagonist (pKi = 9.9) with >31000-fold selectivity over all three human vasopressin receptors hV1aR, hV2R, and hV1bR, with no significant P450 inhibition. Epelsiban has low levels of intrinsic clearance against the microsomes of four species, good bioavailability (55%) and comparable potency to atosiban in the rat, but is 100-fold more potent than the latter in vitro and was negative in the genotoxicity screens with a satisfactory oral safety profile in female rats.

(3R,6R)-3-(2,3-Dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione (69 EPELSIBAN)

A ………………………. gave colorless needles (75%)

mp 140 °C.

1H NMR (CDCl3) δ 7.49 (d, J =7.8 Hz, 1H, pyridyl-4H),

7.26–7.15 (m, 4H, indanyl-arylH),

7.10 (d, J =8.1 Hz, 1H, pyridyl-5H),

6.68 (s, 1H, NCHpyridyl),

6.49 (d, J = 2.8 Hz, 1H, lactam-NH),

4.10 (dd, J = 10.1 Hz, 4.0 Hz, 1H, NCHindanyl),

4.01 (d, J = 4.5 Hz, NCHsec-butyl),

3.75–2.71 (m, 13H, 8× morpholinyl-H, indanyl-3H, -1H, -2H),

2.62 and 2.58 (2s, 6H, pyridyl-2Me,-6Me),

1.64–1.52 (m, 1H, CHHMe),

0.98–0.79 (m, 2H, CHHMe, CHMeCH2),

0.70 (t, J = 7.1 Hz, 3H, CH2Me),

0.45 (d, J = 6.8 Hz, 3H, CHMe).

LCMS m/z 519 (MH+) single component, gradient 2 (tR 2.70 min).

HRMS calcd for C30H38N4O4(MH+) 519.29658, found 519.29667.

HPLC: 100% (tR 10.388 min).

EPELSIBAN BESYLATE SALT

To a ……………………………….give the besylate (3.214 g, 92.6%) as white crystals of 69B

mp 179–183 °C.

1H NMR (CD3OD) δ 8.30 (d, 1H, J = 8.1 Hz, pyridyl-4H),

7.84–7.80 (m, 2H, PhSO3– 2× ortho-H),

7.78 (d, J = 8.3 Hz, 1H, pyridyl-5H),

7.45–7.38 (m, 3H, PhSO3– 2×meta-H, para-H),

7.23–7.09 (m, 4H, indanyl-arylH),

6.08 (broad s, 1H, NCHpyridyl),

4.00 (d, J =4.6 Hz, 1H, NCHsec-butyl),

3.92 (d, J = 9.9 Hz, 1H, NCHindanyl),

3.78–3.39 and 3.14–2.80 (m, 13H, 8× morpholinyl-H, indanyl-3H, -1H, -2H)),

2.79 and 2.78 (2s, 6H, pyridyl-2Me, -6Me),

1.85–1.74 (m, 1H, CHHMe),

1.59–1.48 (m, 1H, CHHMe),

1.15–1.01 (m, 1H, CHMeCH2),

0.92 (d, J =6.3 Hz, 3H, CHMe),

0.85 (t, J = 7.3 Hz, 3H, CH2Me).

LCMS m/z 519 MH+ single components, tR2.72 min;

circular dichroism (CH3CN) λmax 225.4 nm, dE −15.70, E15086; λmax 276 nm, dE 3.82, E5172.

HRMS calcd for C30H38N4O4 (MH+) 519.2971, found 519.2972.

Anal. (C30H38N4O4·C6H6O3S·3.0H2O) C, H, N, S.

References

- Borthwick AD, Liddle J, Davies DE, Exall AM, Hamlett C, Hickey DM, Mason AM, Smith IE, Nerozzi F, Peace S, Pollard D, Sollis SL, Allen MJ, Woollard PM, Pullen MA, Westfall TD, Stanislaus DJ (January 2012). “Pyridyl-2,5-diketopiperazines as potent, selective, and orally bioavailable oxytocin antagonists: synthesis, pharmacokinetics, and in vivo potency”. Journal of Medicinal Chemistry 55 (2): 783–96. doi:10.1021/jm201287w. PMID 205501.

| Cited Patent |

Filing date |

Publication date |

Applicant |

Title |

| WO2003053443A1 |

Dec 20, 2002 |

Jul 3, 2003 |

Glaxo Group Ltd |

Substituted diketopiperazines as oxytocin antagonists |

| WO2006000399A1 |

Jun 21, 2005 |

Jan 5, 2006 |

Glaxo Group Ltd |

Novel compounds |

|

EP2005006760W |

|

|

|

Title not available |

| US6914160 |

Jul 31, 2003 |

Jul 5, 2005 |

Pfizer Inc |

Oxytocin inhibitors |

| US20070254888 |

Jun 21, 2005 |

Nov 1, 2007 |

Glaxo Group Limited |

Piperazinediones as Oxytocin Receptor Antagonists |

| US8202864 * |

Feb 25, 2011 |

Jun 19, 2012 |

Glaxo Group Limited |

Compounds |

| US8716286 |

Oct 28, 2010 |

May 6, 2014 |

Glaxo Group Limited |

Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione |

| US8742099 |

May 20, 2013 |

Jun 3, 2014 |

Glaxo Group Limited |

Compounds |

| US8815856 |

Mar 18, 2014 |

Aug 26, 2014 |

Glaxo Group Limited |

Crystalline forms of (3R, 6R)-3-(2,3-dihydro-1H-inden-2-yl)-1-[(1R)-1-(2,6-dimethyl-3-pyridinyl)-2-(4-morpholinyl)-2-oxoethyl]-6-[(1S)-1-methylpropyl]-2,5-piperazinedione |

| US20120202811 * |

Apr 19, 2012 |

Aug 9, 2012 |

Glaxo Group Limited |

Novel compounds |

Filed under:

PHASE1,

Uncategorized Tagged:

being developed by GlaxoSmithKline,

Epelsiban,

GLAXO,

GlaxoSmithKline,

gsk,

men.,

PHASE 1,

premature ejaculation ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

* Author for correspondence: claude.debellefon@lgpc.cpe.fr

* Author for correspondence: claude.debellefon@lgpc.cpe.fr

László Kocsis holds a Masters degree in Bioorganic Chemistry from the Eötvös Lóránd University in Budapest, Hungary (2001) and a PhD in Organic Chemistry from the Eötvös Lóránd University in Budapest, Hungary (2008). In 2004 he began working as a research chemist at the Reanal Finechemical Company in Budapest, Hungary. He became the Head of the R&D laboratory in 2007 and a manager of production in 2008. In 2011 he joined ThalesNano Inc. as Head of Chemistry. He has experience in organic chemistry, with emphasis on sythesis of amino acid derivatives and peptides, focusing mainly on the following subjects: structure – relationship studies in opiod peptides, methodological studies in the internal solubilization of the sekf-aggregating peptides, industrial scale sythesis of protected amino acid derivatives, and peptides, heterogeneous catalysis, reactions under continuous flow conditions. He is the co-author of 10 pulications and a member of the European Peptide Society.

László Kocsis holds a Masters degree in Bioorganic Chemistry from the Eötvös Lóránd University in Budapest, Hungary (2001) and a PhD in Organic Chemistry from the Eötvös Lóránd University in Budapest, Hungary (2008). In 2004 he began working as a research chemist at the Reanal Finechemical Company in Budapest, Hungary. He became the Head of the R&D laboratory in 2007 and a manager of production in 2008. In 2011 he joined ThalesNano Inc. as Head of Chemistry. He has experience in organic chemistry, with emphasis on sythesis of amino acid derivatives and peptides, focusing mainly on the following subjects: structure – relationship studies in opiod peptides, methodological studies in the internal solubilization of the sekf-aggregating peptides, industrial scale sythesis of protected amino acid derivatives, and peptides, heterogeneous catalysis, reactions under continuous flow conditions. He is the co-author of 10 pulications and a member of the European Peptide Society.

NEWS………….DUBLIN and BUDAPEST, Hungary, Jan. 6, 2015 /PRNewswire/ — Actavis plcand Gedeon Richter Plc. today announced that the U.S. Food and Drug Administration (FDA) has acknowledged receipt of Actavis’ New Drug Application (NDA) resubmission for its atypical antipsychotic cariprazine, a potent dopamine D3/D2 receptor partial agonist with preferential binding to D3 receptors. The Prescription Drug User Fee Act (PDUFA) date is expected to be in the second quarter of 2015…….

NEWS………….DUBLIN and BUDAPEST, Hungary, Jan. 6, 2015 /PRNewswire/ — Actavis plcand Gedeon Richter Plc. today announced that the U.S. Food and Drug Administration (FDA) has acknowledged receipt of Actavis’ New Drug Application (NDA) resubmission for its atypical antipsychotic cariprazine, a potent dopamine D3/D2 receptor partial agonist with preferential binding to D3 receptors. The Prescription Drug User Fee Act (PDUFA) date is expected to be in the second quarter of 2015…….

![VISUDYNE®<br />

(verteporfin) Structural Formula Illustration” /></p>

<p>The chemical names for the verteporfin regioisomers are:</p>

<p>9-methyl (I) and 13-methyl (II) trans-(±)-18-ethenyl-4,4a-dihydro-3,4-bis(methoxycarbonyl)-4a,8,14,19-tetramethyl-23H, 25H-benzo[<i>b</i>]porphine-9,13-dipropanoate</p>

<p>The molecular formula is C<sub>41</sub>H<sub>42</sub>N<sub>4</sub>O<sub>8</sub> with a molecular weight of approximately 718.8. Each mL of reconstituted VISUDYNE contains:</p>

<table class=](http://images.rxlist.com/images/rxlist/verteporfin1.gif)

News…………

News…………

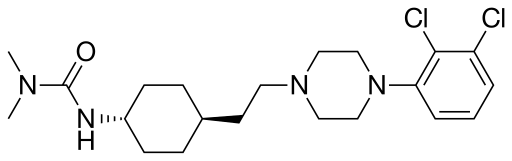

PSORIAIS

PSORIAIS